In various industrial environments, the safety of workers is predominate. One of the critical tools ensuring this safety is gas detectors. These serve as the frontline defense against risky gases, performin a vital role in maintaining safe working conditions across numerous industries, from manufacturing to mining.

Gas detectors are designed to place the front of specific gases, often before they strive chancy concentrations. They can supervise a wide straddle of substances, including carbon paper monoxide, hydrogen sulphide, methane, and volatile organic fertilizer compounds. The ability to notice these gases in real-time is crucial, as many are blanched and odorless, making them unseeable without technical .

The Importance of Gas Detectors

The consequences of ignoring gas hazards can be dire. In industries such as oil and gas, chemical manufacturing, and mining, exposure to nephrotoxic or flammable gases can lead to terrible health risks, including respiratory issues, neurological damage, and even fatalities. Gas explosions can also result in ruinous accidents, causation damage to prop and loss of life. Thus, the integration of gas detectors into refuge protocols is not just a regulative prerequisite; it is a indispensable component of workplace safety.

Types of Gas Detectors

There are two main types of gas detectors: unmoving and portable. Fixed detectors are installed in specific locations to continuously ride herd on gas levels in areas where hazards are unsurprising. These systems are often wired to alarms that trigger off when gas concentrations top safe thresholds, providing immediate warnings to workers and sanctionative fast evacuation if necessary.

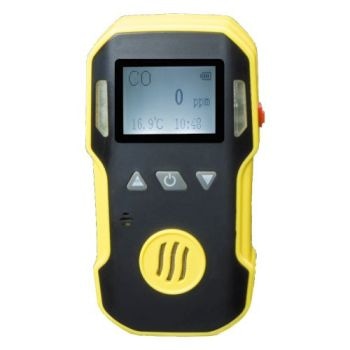

Portable gas detectors, on the other hand, are worn by mortal workers and allow for personal monitoring while they sail through different environments. These are invaluable in situations where workers may encounter gas hazards unpredictably, such as during maintenance activities or emergency reply scenarios. Equipped with features like sonic alarms and vibration alerts, outboard detectors ascertain that workers welcome immediate feedback on their refuge position.

Enhancing Safety Protocols

The execution of gas detectors is often complemented by comprehensive examination safety training. Workers need to be enlightened not only on how to use these but also on the meaning of the gases they ride herd on. Understanding the potential dangers and recognizing the signs of gas exposure are indispensable skills that can save lives. Regular upkee and standardisation of best combustion analyzer s are also necessity to ensure their dependability and truth.

Moreover, advancements in applied science have led to the of ache gas signal detection systems that integrate with broader refuge management software. These systems can ply real-time data depth psychology, historical veer monitoring, and predictive alerts, allowing refuge managers to take proactive measures to mitigate risks before they intensify.

Conclusion

As industries continue to evolve and the for refuge increases, gas detectors will stay a cornerstone of proletarian tribute. By providing real-time monitoring of hazardous gases, these devices help produce safer work environments, finally rescue lives and reduction the risk of accidents. In a worldly concern where work refuge cannot be compromised, gas detectors stand as argus-eyed guardians, ensuring that workers can do their duties with confidence and surety. Investing in these technologies and the preparation to use them in effect is an essential step toward a safer future for all workers across various industries.